Serial No. 215

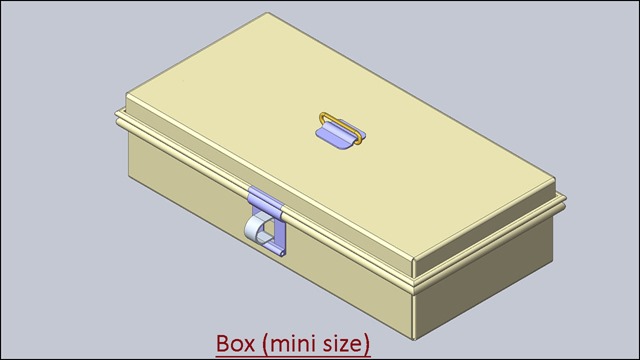

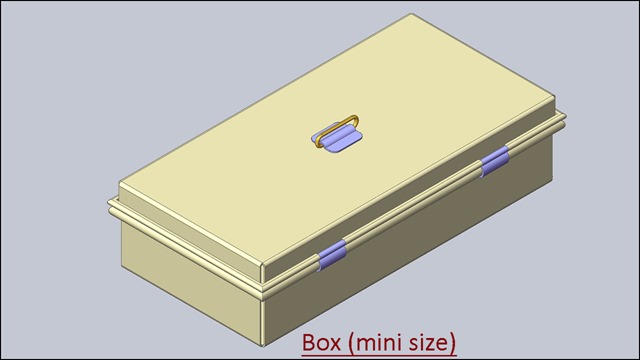

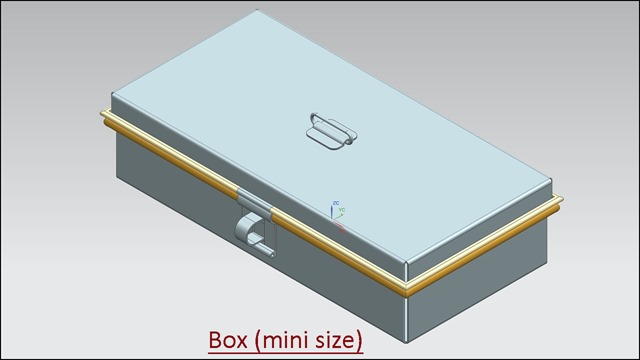

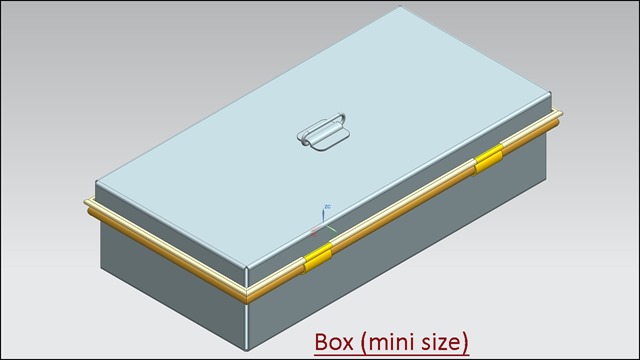

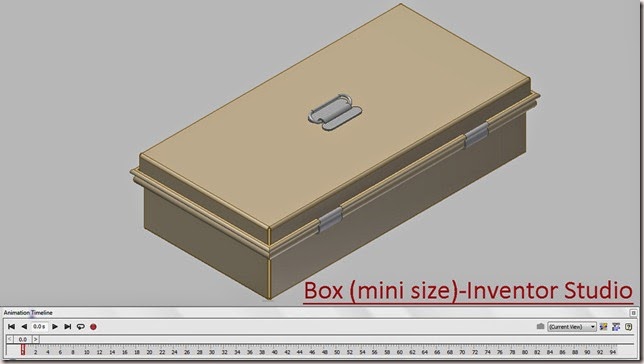

Animation displayed in Box (mini size) -- SolidWorks 2017 (with caption and audio narration)

In this video, we will demonstrate how to apply the different type of mates in the assembly environment for creating the animation in SolidWorks 2017.

Click the following link to get the model file: - http://bit.ly/30MboTG

Transcription of the Video

- Create a new assembly with an inch template.

- And place the ‘Part1’ file in the assembly.

- When the first part file is placed in the assembly, the part remains as a grounded component.

- This part does not need to place any mates.

- Go to the ‘View Orientation’ tab and choose an ‘Isometric’ view.

- Activate the ‘Insert Components’ command and place the ‘Part3’ file in the assembly.

- Apply a ‘Coincident’ mate between the Front face of ‘Part1’ and Back face of ‘Part3’.

- Apply a ‘Coincident’ mate between Front Plane of the assembly and Front Plane of ‘Part3’.

- Apply a ‘Distance’ mate between the top face of ‘Part3’ and ‘Part1’.

- Set the distance value 0.688 inches and click OK.

- Activate the ‘Insert Components’ command and place the ‘Part6’ file in the assembly.

- Apply a ‘Concentric’ mate between the inner circular face of ‘Part6’ and an outer circular ring of ‘Part1’.

- Apply a ‘Coincident’ mate between the back face of ‘Part1’ and back face of ‘Part6’.

- Save the assembly with the name ‘Base Assembly’.

- Apply a ‘Distance’ mate between the side face of ‘Part1’ and ‘Part6’.

- Set the distance value 2.564 inches and click OK.

- In the same manner, place a copy of ‘Part6’ in the assembly and mate it with ‘Part1’.

- Create another new assembly and place the ‘Part2’ file in the assembly.

- Open the visibility of Front Plane of assembly and turn on the ‘View Planes’ button.

- Open the visibility of Top Plane of ‘Part2’.

- Right-click on the ‘Part2’ file and select ‘Float’ option.

- Apply a ‘Coincident’ mate between the Top Plane of ‘Part2’ and Front Plane of Assembly.

- Turn off the visibility of planes.

- Apply a Coincident mate between Right Plane of ‘Part2’ and Right Plane of ‘Assembly2’.

- Save the assembly, name it as ‘Lid Assembly’.

- The part is not fully defined in the assembly, so that apply another ‘Coincident’ mate between the Top plane of Lid assembly and the Front plane of ‘Part2’.

- Activate the ‘Insert Components’ command and place the ‘Part7’ file in the assembly.

- Apply a ‘Coincident’ mate between the top face of ‘Part2’ and back face of ‘Part7’.

- Apply a ‘Coincident’ mate between Front Plane of Lid assembly and Front Plane of ‘Part7’.

- Apply a ‘Coincident’ mate between Right Plane of the ‘Part7’ and Right Plane of ‘Lid assembly’.

- Place the ‘Part5’ file in the assembly.

- Apply a ‘Concentric’ mate between the outer circular face of ‘Part5’ and inside face of the hole of ‘Part2’.

- Apply a ‘Coincident’ mate between Front Plane of ‘Part5’ and Front Plane of ‘Lid Assembly’.

- Apply a ‘Coincident’ mate between Right Plane of ‘Lid Assembly’ and Right Plane of ‘Part5’.

- Now the part is Fully Defined in the assembly.

- Go to the ‘Evaluate’ tab and check the interference between two components by using ‘Interference Detection’ command.

- Save and close all the assembly files.

- Create a new Assembly file, it is our main assembly to create animation, and place the ‘Base Assembly’ file in the assembly.

- Choose an Isometric View, right-click in the design area and activate the ‘View Orientation’ command.

- In the Orientation dialogue box, select the ‘New View’ option.

- Set the ‘Named View’ as ‘View-1’ and click OK.

- Save the assembly by the name ‘Box (mini size) with Animation’.

- Activate the ‘Insert Components’ command and place the ‘Lid Assembly’ file.

- Apply a ‘Concentric’ mate between inside hole of the hinge and outer circular face of wire.

- Apply a ‘Coincident’ mate between the side face of the hinge and face of slot of lid.

- Drag the Lid Assembly and see the result, the ‘Lid Assembly’ rotates on the base of the hinge.

- Place the ‘Part4’ file in the assembly.

- Apply a ‘Concentric’ mate between the hole of the ‘Part4’ and outer circular face of wire.

- Apply a ‘Coincident’ mate between the side face of ‘Part4’ and face of slot of lid.

- Apply a ‘Tangent’ mate between the bottom face of the lid and outer circular ring of ‘Part1’.

- Apply a ‘Coincident’ mate between the front face of ‘Base Assembly’ and back face of ‘Part4’.

- Place the ‘Part8’ file in the assembly.

- Turn off the visibility of the sketch of ‘Part8’ by using ‘View Sketches’ command.

- Apply a ‘Concentric’ mate between ‘Axis1’ of the Lid assembly and circular face of ‘Part8’.

- Apply a ‘Coincident’ mate between the Front Plane of ‘Part8’ and Front Plane of main assembly.

- Apply a ‘Tangent’ mate between the cylindrical face of ‘Part8’ and the top face of ‘Part7’.

- Check the interference between Handle and base.

- Suppress the ‘Tangent1’, ‘Coincident3’ and ‘Tangent2’ mates.

- Apply an ‘Angle’ mate between the Right Plane of ‘Part8’ and the top face of ‘Part7’.

- Set the angle value to 12.46923 degrees and Click OK.

- Change the name of the angle mate as ‘Drive-1’.

- Unsuppress the ‘Tangent1’ mate and apply an ‘Angle’ mate between the back face of the ‘Part4’ and the front face of the ‘Part1’.

- Set the angle value to 0 degree and Click OK.

- Change the name of the angle mate as ‘Drive-2’.

- Suppress the ‘Tangent1’ and ‘Drive-2’ mates.

- Drag the ‘Lid Assembly’ and turn on the ‘View Planes’ button.

- Apply the ‘Angle’ mate between Plane3 of ‘Part1’ and back face of ‘Lid Assembly’.

- Set the angle value to 0 degree and Click OK.

- Unsuppress the ‘Drive-2’ mate and change the name of the ‘Angle6’ mate as ‘Drive-3’.

- In the next section of this video, we will create three additional views with in alternate position of this model before entering the ‘Motion Study’ environment.

- These saved views will be used later in animation timeline.

- Click on the ‘Motion Study’ tab and click the ‘Collapse Motion Manager’ button.

- Choose ‘View-2’ in the Orientation dialog box.

- Click ‘Expand Motion Manager’ button.

- Go on the ‘Orientation and Camera’ tab in the animation timeline.

- Right-click the View-5 key and select ‘Replace Key’ option.

- Right-click on the animation timeline, move the time bar at 2 second.

- Copy the ‘View-2’ key and paste it.

- Pause 2 seconds on the ‘View-2’ position.

- Move the time bar at 7 second and place the new key.

- Choose ‘View-3’ in the Orientation dialogue box.

- Right-click on the View-2 key and select ‘Replace Key’ option.

- Time required 5 seconds in changing from View-2 to View-3 position.

- In the Mates folder, copy the ‘Drive-1’ mate key.

- Move the time bar at 9 second and paste the key.

- Pause 2 seconds on the ‘View-3’ position.

- Move the time bar at 24 second and place the new key.

- Double click on the new key to modify the key and set the specified angle 167.53077 degrees and click OK.

- Move the time bar at 26 second, copy the ‘View-3’ key and paste it.

- Move the time bar at 31 second and place the new key.

- Minimize the animation timeline and set the view as ‘View-4’ position.

- Expand the animation timeline and choose ‘Replace Key’ option.

- Time consume 5 seconds in changing from View-3 to View-4 position.

- Move the time bar at 33 second.

- Copy the ‘Drive-2’ mate key and paste the key.

- Move the time bar at 48 second and place the key.

- Modify the key and set the angle value to 90 degree.

- Move the time bar at 50 second, copy the ‘View-4’ key and paste the key.

- Move the time bar at 55 second and paste the key.

- Choose ‘View-5’ in the Orientation dialogue box.

- Right-click on the View-4 key and select ‘Replace Key’ option.

- Move the time bar at 57 second, copy the ‘Drive-3’ mate key and paste the key.

- Move the time bar at 72 second and place the new key.

- Modify the key and set the angle value to 90 degree.

- The time spent for each Drive mates will be of 15 seconds.

- Click ‘Calculate’ button to calculate the motion study.

- Stop the animation and click ‘Play from Start’ button and start the animation.

- Follow the same steps which were done earlier to create the animation in reverse direction.

- Now start the animation to see the result.

- Save the assembly.