Serial No. 288

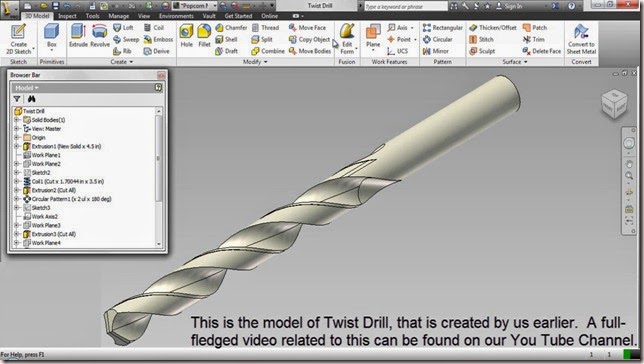

iTwist Drill -- Autodesk Inventor 2013 Tutorial (with caption and audio narration)

In this part modelling tutorial of ‘Autodesk Inventor,’ we will create a model named ‘iTwist Drill ’. We will start our work by defining some User Parameters that will be used to create a mathematical relation between the dimensions applied in the due course of modelling the ‘Twist Drill’.

Then we will create a circle and extrude it. Next, we will create some user-defined work planes at specified spots. These planes will be used to draw some more sketches, to be used as a base profile for cutting flute (rounded grove) over the round bar. Then a coil feature and an extrude feature with a cut operation will be applied to create flute. Then using a circular pattern tool we will duplicate the same at an angle of 180°. Next, we will create some sketch profiles to cut lip and lip relief on the edge of the drill bit. The process will be the same as applied earlier. Later more coil feature will be applied to complete the model.

The highlight of the videos is the after creating the model with full parameters the iPart creation of the model is also displayed.

Watch the video to understand all the process clearly

.................................................................

To more understand the creation process of an iParts in Autodesk Inventor watch a related video at the following link:---

https://youtu.be/KNCrDJdPm-s.

- Create a new inch part file.

- Go to the Manage tab and activate the ‘Parameters’ command.

- Add the Parameter name ‘diaMajor’ in the ‘User Parameters’ tab by using 'Add Numeric' key and set the value 7/16 ul in the equation area.

- In the same manner, add two more parameters and click OK.

- Create a new sketch over XY Plane.

- Create a circle and place the dimension, select the ‘List Parameters’ and choose diaMajor and click OK.

- Right-click the dimension and select ‘Expression’.

- Finish the sketch and activate the ‘Extrude’ command.

- The sketch profile will automatically select and set the distance value relating in terms of parameters, click OK.

- Save the file as ‘iTwist Drill’.

- Change the colour of the model as you wish.

- Activate the ‘Plane’ command and create a plane inside from this face.

- And place the dimension.

- Change the name of the plane as ‘ShankEnd’ and create an Axis in the centre of the part, name it as majorAxis.

- Activate the Axis command and select WorkPlane1 and XZ plane.

- A new axis will form on the intersection of these two planes.

- Change the name of this axis, call it as ‘Intersection Helix Origin Planes’.

- Now activate the ‘Point’ command and create a work point at the intersection of this vertical plane and axis .

- Activate the ‘Parameters’ command and add HelixAngle in the ‘User Parameters’ tab with the help of ‘Add Numeric’ button.

- Now see, different kinds of measurement options are visible here, you choose only one option at a time as per your design.

- In the Unit Type dialogue box, select degree option and click OK.

- Set the Helix angle to 30 degrees and click OK.

- Activate the ‘Plane’ command and select ‘Intersection Helix Origin Planes’ axis and XZ Plane, set the specified angle relating to parameters.

- Change the name of this plane, as ‘helix Origin Plane1’.

- Close the visibility of ‘ShankEnd’ plane and ‘Intersection Helix Origin Planes’ axis.

- Add two more parameters name as ‘web’ and ‘diacutter’.

- Create a new sketch on this plane.

- Rotate the model parallel to the inclined plane by using ‘Look at Plane’ command.

- Activate the slice graphics command.

- Take the project of ‘Intersection Helix Origin Planes’ and ‘Work Point1’ with the help of ‘Project Geometry’ command.

- Create a circle and set the desired dimensions to fully constrain the sketch.

- Finish the sketch and change the name of the sketch as ‘diacutter’.

- Add one more parameter call it as ‘helixPitch’.

- Activate the ‘Coil’ tool, it will automatically select the sketch profile, select the major axis and select the ‘Cut’ option in the Coil dialogue box.

- Go to the Coil Size tab and select the ‘Pitch and Height’ option.

- In the Pitch area select from the List Parameters click ‘HelixPitch’ and in the Height area select from the List Parameters, click ‘fluteLen+diaMajor’.

- Click OK to create the coil feature.

- Open the visibility of ‘diacutter1’ sketch.

- Activate the ‘Extrude’ command, select the ‘All’ option in the Extents field and choose ‘Cut’ option and click OK.

- Change the name of this extruded cut feature as ‘blend’.

- Activate the ‘Circular Pattern’ tool and select the Coil1 and blend feature from the browser bar, select the major axis as a rotation axis and fill the value of Occurrence count and angle.

- Click OK to execute the command.

- Create a new sketch on this face.

- Take the project of these four curves and circle.

- Draw a circle and tangent it to this curve.

- Select all the sketches and convert it construction geometry.

- Create two points on the intersection point of this circle and curve.

- Draw a line passing through the centre of the circle and add coincident constraint between line and point.

- Take the project of ‘Intersection Helix Origin Planes’ axis.

- Set the angular dimension between these two lines.

- Finish the sketch and change the name of the sketch as ‘TipRef1’.

- Make a Work Axis on this line.

- Change the name of the axis as ‘lipReliefGeom’.

- Activate the ‘WorkPlane’ command and select these two axes.

- Change the name of the plane as ‘lipReliefGeom’.

- Now the plane is created along the axis.

- Activate the ‘Angle to Plane around Edge’ command.

- Select the ‘lipReliefGeom’ plane and ‘majorAxis’, set the angle 90 degrees, click OK.

- Add the parameter ‘tipangle’ and set the angle 118 degrees.

- Create a new sketch over the ‘lipReliefGeom’ plane.

- Activate slice graphics command, take the project of this edge and major axis.

- Draw a vertical line and add coincident constraint between the midpoint of a line and centre line.

- Draw a horizontal line and join it to the midpoint of the projected line.

- In the same manner, draw another line on the opposite side of the sketch and add the equal constraint between these two horizontal lines.

- Add the Symmetric constraint between these two lines.

- Set the dimensions relating to the parameters on all the sketches.

- Finish the sketch and activate the ‘Extrude’ command.

- Select the sketch profile, click ‘Cut’ option and select ‘Symmetric’ option, select ‘Through all’ option and Click OK.

- Change the name of Extrusion as ‘ptangle’.

- Add the parameters ‘lip relief angle’ and ‘lip clearance angle’ and finally set the angle values.

- Activate the ‘WorkPlane’ command, select this face and edge and set the value 90-degree, click OK.

- In the same way, create another work plane in opposite side of the previous plane, the two workplanes has been created along the taper face.

- Change the name of workplane as ‘liprelief’.

- Create a new sketch over the ‘lipRelief’plane.

- Activate the ‘Look at plane’ command and select the ‘lip relief’ plane for rotating the model along the plane.

- Activate the slice graphics command, take the project of ‘major axis’ and ‘lipReliefGeom’ axis.

- Draw a circle over the intersection point of vertical and horizontal lines.

- Set the dimension, select ‘diaMajor’ from list parameters.

- Select all the sketch and convert it to construction geometry.

- Draw a horizontal line and a vertical line.

- Draw another line from the endpoint of a vertical line passing through center line and connect to the opposite side of the circle.

- Apply the angular dimension, select ‘lipClearanceAngle’ from list parameters.

- Apply another angular dimension, select ‘lipReliefAngle’ from list parameters.

- Create a line from the endpoint of horizontal line and connect to the opposite side of the circle.

- Finish the sketch and activate the ‘Extrude’ command.

- Choose the ‘Cut’ option → select ‘Symmetric’ option → select ‘All’ option in the Extents field and click OK.

- Change the name of Extrusion Cut as ‘liprelief’.

- Activate the ‘Circular Pattern’ tool and select the liprelief cut feature → click ‘Continue’ button for selecting as a rotation axis → set the occurrence count and angle value and Click OK.

- Activate the ‘Parameters’ command and add the one more parameter named ‘fluteReliefSetback’.

- Set the desired value in terms of equation.

- Click Ok.

- Create a new sketch over the YZ Plane and activate the slice graphics command.

- Take the project of the major axis and shankEnd workplane.

- Create a rectangle and apply the preferred dimensions.

- Change the name of the sketch as ‘clearanceDia’.

- Activate the ‘Coil’ tool → select the major axis → go to the Coil Size tab → select the ‘Pitch and Height’ option.

- In the Pitch area select ‘HelixPitch’ from the List Parameters and in the Height area select ‘fluteLen+helixpitch’ from the List Parameters.

- Go to the Coil Shape tab, select ‘Cut’ option and click OK.

- Open the visibility of ‘clearanceDia’ sketch.

- Activate the ‘Coil’ tool once again → choose ‘Cut’ option → select the Coil size tab but this time ‘Pitch and Revolution’ should be selected in ‘Type’ area in place of ‘Pitch and Height’ option → set the pitch value as ‘helixPitch’ and set the revolution value 0.25 and taper angle 3 degrees.

- Click the ‘Axis’ button to go in the reverse direction of coil feature.

- Click OK to create coil feature.

- Replicate the pattern of these two coil feature twice times with the help of ‘Circular Pattern’ tool.

- Activate the ‘Create iPart’ command.

- Remove all the key except ‘diamajor’, ‘oal’, ‘fluteLen’ parameters in the ‘ipart Author’ dialogue box.

- Insert new row for creating a new member of different size.

- Change the value of diamajor, oal and fluteLen column.

- Click Verify button to apply the new member.

- Click OK.

- Go to the browser bar, under the Table, Let watch here, two row has been created.

- The first row is default size and the second row is our new size.

- Select each one by one to activate it and observe the result.

- Activate the ‘Edit via Excel Spreadsheet’ command.

- In the same manner, several members have been created with different sizes in the excel sheet.

- We showed some examples of different sizes.

- Save the excel file and close it.

- Let see here it automatically updates all the family members, which had been added in the browser bar.

- Select each one by one to activate it and observe the result.

- Save the part file.