Serial No. 7

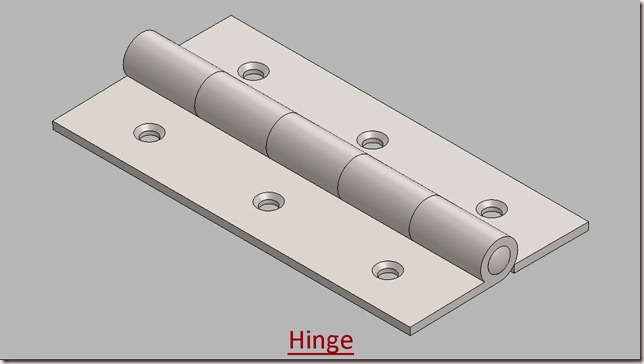

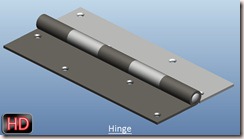

Hinge Modelling along with Animation--Solid Edge ST9 Tutorial

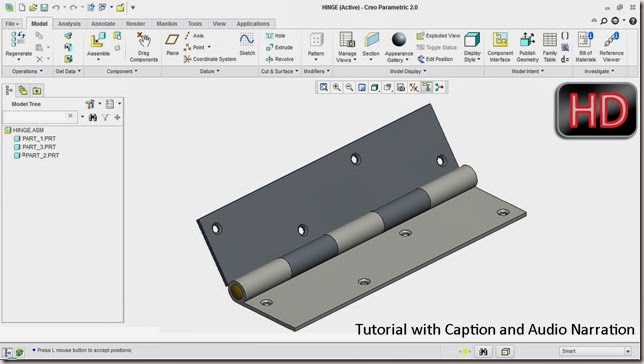

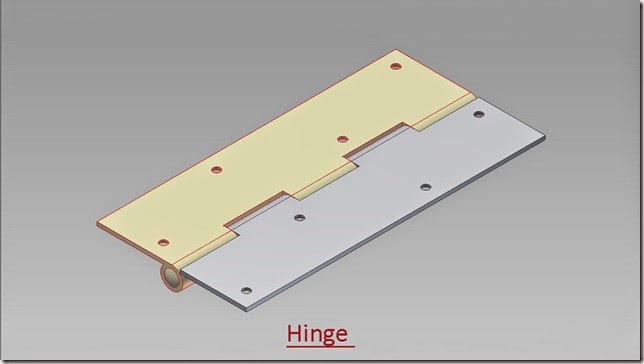

In this video, we will describe you how to made a Hinge with various part modelling tools. How to place parts in the assembly and afterward give the 'Rotational Motor' command on the under-constrained part.

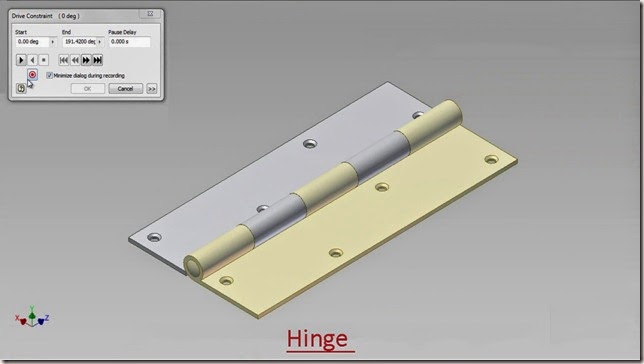

When you click the Simulate Motor command, the Motor Group Properties dialog box is displayed so you can specify which motors you want to use, the default duration, and other similar options. When you click OK, the Animation Editor is displayed so you can run the simulation. To run the simulation, click the Play button.

Click the following link to get the model file: - http://bit.ly/2oZXFeM