Serial No. 29

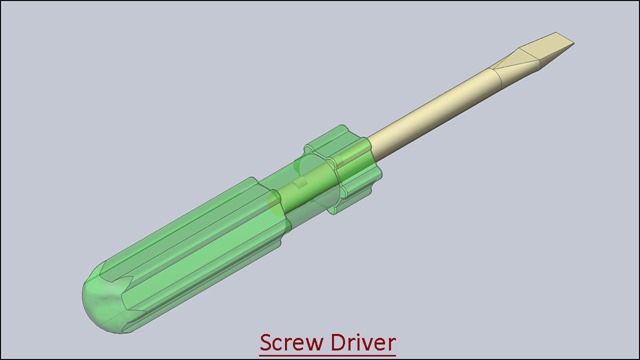

In this Solid Edge Tutorial we will describe how to build the model ‘Allen Screwdriver’. The edge of Allen screwdriver has been constructed by different surface tools like Bound, Stitch, Derived etc. It is a Part and Assembly modelling tutorial. This assembly consist 2 part files Screw Driver and Handle that are positioned according to design intent by using Assembly Constraints.

It will cover the following topics.

........................................................................................................

• Creating 2D Sketches on different Planes.

• Use some sketch constraints as Connect, Horizontal/Vertical, and Equal etc. that are applied on during sketch creation.

• Use solid and surface feature command such as Revolved (Surface), Bounded, Stitched, Extrude, Cut, Circular Pattern, Loft, Subtract, Round etc.

• How to patterning an arc and a line by using ‘Derived’ command, this is the easiest way to create a sketch pattern.

• How to create a line by using ‘3D Line’ command in 3D Sketch environment.

• How to create a feature between circle and point by using ‘Loft Protrusion’ command.

• How to change the color of the model by using ‘Part Painter’ tool.

• How to insert component into the assembly using drag and drop from parts library by using ‘Insert Component’ command.

• How to mate the parts by using ‘Flash Fit’ command in the assembly.

• How to lock the rotation of the component by using ‘Lock Rotation’ option in ‘Flash Fit’ command in the assembly.

• Use the ‘Subtract’ command (Boolean) to remove the tool body volume from selected target bodies in the assembly. You can select multiple target bodies and multiple tool bodies.

• How to hide all components except the selected components by using ‘Isolate’ command in the assembly.

Click the following link to get the model file: - http://bit.ly/2pWfHiu