Serial No. 30

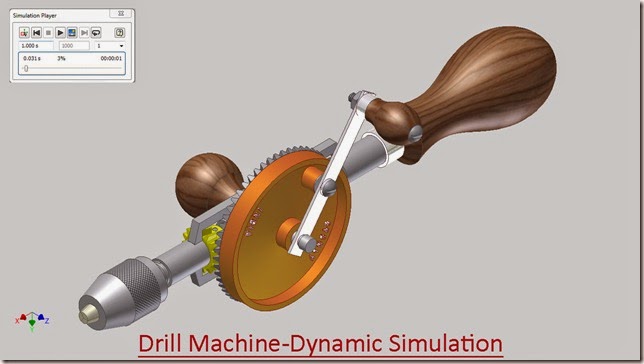

Drill Machine-Dynamic Simulation-Autodesk Inventor 2012 (with caption and audio narration)

In this video, we will demonstrate how to apply the different type of mates in the assembly environment for creating the Dynamic Simulation of the ‘Drill Machine’.

Click the following link to get the model file: -http://bit.ly/2ncLp9z

Transcription of Video

Display of Motion in Drill Machine through Dynamic Simulation

- Create a New ‘Standard (in).iam’ Assembly and save it with the name ‘Drill Machine-Dynamic Simulation’.

- Select Place component from the marking menu and place the Frame in the Assembly.

- Place Handle-1 and Handle Cap-1 in the Assembly.

- Start the Constrain Command and choose Insert Mate from the type option.

- First select the inner circular edge of Handle Cap, then select outer circular edge of Handle and click Ok.

- Give another Insert Mate between Inner edge of Handle Cap and circular edge of Frame as displayed.

- Re-orient the design window using View Cube.

- Set the current view as Home View using the toggle next to View Cube.

- Place Gear Wheel and Gear in the Assembly.

- Apply a Mate Constraint between Axis of Gear Wheel and Axis of Gear.

- Next, apply a Mate Constraint between face of Gear Wheel and face of Gear.

- Apply another Mate Constraint between YZ Plane of Gear Wheel and XZ Plane of Gear.

- Re-orient the Gear Wheel with respect to Frame using Rotate Component Tool.

- Apply an Axis Mate between Gear Wheel and stud of Frame.

- Place Spindle in the Assembly.

- Apply a Mate Constraint between Axis of Frame and Axis of Spindle.

- Next, apply a Mate Constraint between inner face of supporting cylinder of frame and back face of the spindle.

- Place Pinion-2 in the Assembly.

- Apply a Mate Constraint between Axis of Pinion-2 and Axis of Spindle.

- Apply an Axis Mate between hole on Pinion-2 and hole on Spindle.

- Place Locking Pin in the Assembly and fix it inside the hole of Pinion using Insert Mate.

- Place Pinion-1 in the Assembly.

- Align the Pinion-1 to match it with the Frame.

- Apply a Mate Constraint between Axis of Frame and Axis of Pinion-1.

- Select Pinion-1, Pinion-2 and Gear, then right click in the design window, choose ‘Isolate’ from the context menu.

- Set the Browser from Assembly view to Modeling View.

- Locate the Intersection Point of Pinion-2 inside the Browser Bar.

- Apply a Mate Constraint between the Intersection Point of Pinion-2 and Intersection Point of Gear.

- In the same manner, apply a Mate Constraint between the Intersection Point of Pinion-2 and the Intersection Point of Pinion-1.

- Activate Motion Constraint; first select the Axis of Pinion-1 and afterward the Axis of Gear.

- Enter the value 15/56 in the Ratio Input box and click Apply.

- Apply same step as above to give motion constraint between Pinion-2 and Gear.

- Right click in the design window, choose Undo Isolate from the context menu.

- Place Chuck in the Assembly.

- Apply a Mate Constraint between the Axis of Spindle and the Axis of Chuck.

- Place a Mate Constraint between inner circular face of Chuck and front face of Spindle.

- Place another Mate Constraint between YZ Plane of Chuck and YZ Plane of Spindle.

- Place Three instances of Jaw in the Assembly.

- Apply an Axis Mate between two subsequent Jaws.

- Next, apply a Mate between their edges.

- Apply a Flush Mate between their end faces.

- In the same manner, constraint the third Jaw.

- Apply a Mate Constraint between inner circular face of Chuck and rear face of Jaw.

- Apply a Mate Constraint between the Axis of Chuck and the Axis of Jaw.

- Place a Mate Constraint between YZ Plane of Chuck and YZ Plane of any one Jaw.

- Place Handle-2 and Handle Cap-2 in the Assembly.

- Apply an Insert Mate between inner circular edge of Handle Cap-2 and outer circular edge of Handle-2.

- Position the Handle Cap-2 in respect of the stud of Frame by using Rotate Component Tool.

- Apply an Insert Mate between front circular edge of Handle Cap-2 and inner circular edge of stud.

- Place Handle Connecting Plate in the Assembly.

- Apply an Insert Mate between edge of the hole on Handle Connecting Plate and inner circular edge of stud.

- Place Washer-1 in the Assembly.

- Apply an Insert Mate between edge of the hole on Washer-1 and edge of the hole on Gear Wheel.

- Apply a Mate Constraint between YZ Plane of Handle Connecting Plate and Axis of the hole on Gear Wheel.

- Place Screw-2 in the Assembly.

- Apply an Insert Mate between inner circular edge of Screw-2 and edge of the hole on Handle Connecting Plate.

- Place Handle-3 and Handle Cap-3 in the Assembly.

- Fit the Handle Cap-3 over the Handle-3 with the help of Insert Mate.

- Apply another Insert Mate between the Handle Cap-3 and hole on the Handle Connecting Plate.

- Place Screw-1 and Nut in the Assembly.

- Fix the Screw-1 on the Handle-3 with the help of Insert Mate.

- Fix the Nut on the Screw-1 by applying Insert Mate.

- Open the Visibility of surfaces named ‘Pitch Diameter’ of Pinion-2, Pinion-1 and Gear.

- ‘Isolate’ the Pinion-1, Pinion-2 and Gear in the Assembly.

- Activate the Dynamic Simulation Tool from the Begin Panel of Environments Tab.

- Select Insert Joint in the Marking menu.

- Select ‘Rolling: Cone on Cone’ from the drop down menu of Insert Joint dialog box.

- Select Pitch Diameter of Pinion-2 in ‘Component 1’ option and select Pitch diameter of Gear in ‘Component 2’ option and click Apply.

- In the same manner select Pitch Diameter of Pinion-1 and select Pitch diameter of Gear and click Ok.

- Finish Dynamic Simulation and return to Assembly Modelling environment.

- Close the visibility of surfaces named ‘Pitch Diameter’ of Pinion-1, Pinion-2 and Gear.

- Right Click in the design window and click ‘Undo Isolate’ option.

- Activate Dynamic Simulation Tool.

- Select Revolution:2 joint in the Browser under the Standard Joints folder, right click and select Properties from the context menu.

- Click dof 1 (R) tab and select Edit imposed motion button and check the Enable imposed motion option.

- Click the arrow to expand the input choices, and click Constant Value.

- Enter the value 360 deg/s and click Ok.

- In Simulation Player, fill the value 1000 in the Images field area.

- Clear the screen by activating the Clean Screen command.

- Click Run in the Simulation Player to display motion in Drill Machine.

No comments:

Post a Comment